Shutdown Services

Shutdown maintenance of static equipment in Oil Refineries, Gas and Petrochemical Plants.

|

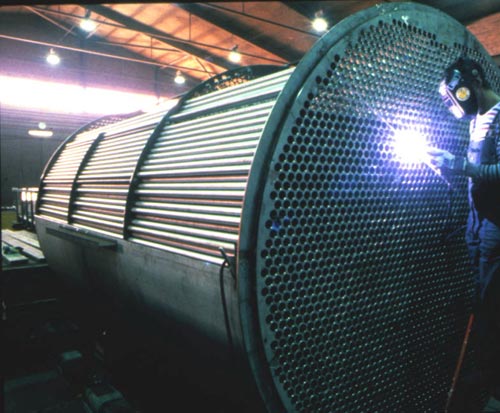

Heat Exchangers: We do manual cleaning, Hydro jetting, cleaning of complete Heat Exchanger, Hydro testing & replacement.

|

| 1

|

U Tube type

|

2

|

Floating Head type

|

3

|

Fixed Tube type

|

| 4

|

Tube in Tube type

|

5

|

Plate type

|

6

|

Block type (Graphite)

|

| 7

|

Breach Lock type

|

8

|

Box Type

|

9

|

Kettle type

|

|

Columns: Removal/Refixing of Trays, Packings, Bubble caps, Mechanical cleaning of internal walls of column with hand tools and as well with Pneumatic & Electrical tools, cleaning of internal parts, Repairing of Trays, loading of packing rings in column and Hydro test of column.

|

| 1

|

Vacuum Columns

|

2

|

Propyne Columns

|

3

|

Rerun Columns

|

| 4

|

Stabilizer Columns

|

5

|

Degasser Columns

|

6

|

Absorber Columns

|

| 7

|

Stripper Columns

|

8

|

Recovery Columns

|

9

|

Heads Columns

|

| 10

|

Product Columns

|

11

|

Quench Columns

|

12

|

Fractionator Columns

|

| 1

|

Sieve type trays

|

2

|

Bubble cap type trays

|

3

|

Valve type trayss

|

| 4

|

Packing (Racing ring, Ceramic Saddle, Jump-pack and

Structure Packing)

|

|

|

|

|

|

Reactors: Services include removal/refixing of internals, cleaning of reactor, Hydro testing in Reactor, Grit blasting, catalyst loading/unloading.

|

| 1

|

Tubular type

|

2

|

Vessels and Column type

|

|

Vessels: Cleaning with hand tools and pneumatic tools and Hydro testing of all type of vessels, tanks, spheres, agitators.

|

| 1

|

Glassed Line type

|

2

|

Sphere type

|

3

|

Tanks type

|

| 4

|

Bullet type

|

|

|

|

|

|

Valves: Overhauling of all types of Safety, control, N.R.V, Gate/Globe valves.

|

|

|

|

|

|

|

|

|